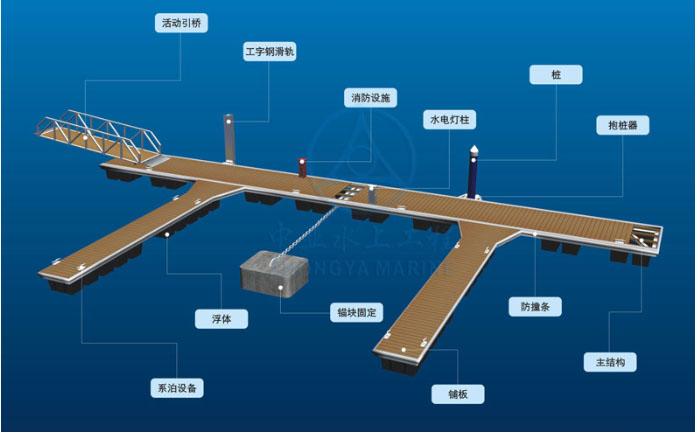

As a supporting facility for yachts, the marina is mainly to provide a place for yachts to dock and supply water and electricity. The structure of the yacht pier mainly includes movable approach bridges, main pier passages, pier branch passages, fixed installations, mooring installations, hydroelectric installations, anti-collision facilities, etc. A qualified marina should be repaired internally and externally, the internal structure is safe and stable, and the exterior structure is beautiful and humane. Zhongya Company is an early enterprise engaged in the construction of yacht piers in China, and is committed to creating practical and beautiful yacht piers for every customer.

1.Noun definition

As a supporting facility for yachts, the marina mainly provides a place for yachts to dock, repair and maintain, supply water and electricity, and enter and disembark tourists. The structure of the yacht pier mainly includes movable approach bridges, main pier passages, pier branch passages, fixed installations, mooring installations, hydroelectric installations, anti-collision facilities, etc. The designer will design the most ideal yacht pier while ensuring quality and safety by referring to factors such as ship type, water depth, tides, current conditions, and the size of wind and waves.

2.Type of terminal

Combined yacht marina

The pontoon is assembled in a specific form, and steel frame panels can also be laid as needed. The material of the pontoon is high-molecular high-density polyethylene, which has the characteristics of wear resistance, corrosion resistance, and strong impact resistance. The pontoon has a unique modular design and can be freely combined; the surface is non-slip design, safe and stable.

This kind of yacht dock has strong flexibility for independent expansion, simple installation method, short construction period, and almost no maintenance and maintenance costs. It is widely used in fields such as floating docks, motorboat docks, water swimming pool platforms, water stages, pontoons, and water working platforms.

Steel structure yacht marina

The steel structure yacht pier is laid with steel frames and panels on the basis of the floating body. The main skeleton is a hot-dip galvanized steel structure, which is fixed with a floating body through a special connection, which effectively strengthens the stability of the wharf; the panel can be made of hardwood, pine or plastic wood composite materials, and the surface of the wooden material makes the wharf more unique and elegant. It can be equipped with ancillary facilities such as water and electricity, security, mooring cables, and railings.

Steel structure yacht piers are currently the most widely used piers, which can fully meet the design requirements of yacht clubs and small and medium-sized commercial piers.

Aluminum structure yacht marina

Aluminum alloy yacht docks, excellent corrosion resistance, convenient transportation and installation methods, and super bearing capacity, these characteristics make it almost a permanent use of one installation. Even if the pontoons and panels are aging for a long time, as long as some parts are replaced, the aluminum alloy dock will have a new look. The aluminum frame is made of marine-grade 6061 aluminum alloy, T6 heat treatment, and MIG welding. The surface has been scientifically treated to enhance the oxidation resistance and corrosion resistance of the frame. After the welded aluminum alloy frame is connected and fixed with the floating body, the surface is covered with solid wood or plastic wood panels, and it is equipped with water and electricity, security, mooring cables, railings, approach bridges and other auxiliary facilities.

Concrete marina

The concrete structure yacht pier developed by the introduction of American technology has many advantages such as beautiful atmosphere, corrosion resistance, frost resistance, high buoyancy, good stability, strong wind and wave resistance, strong frost resistance and corrosion resistance, long service life, low maintenance cost, etc. , Can adapt to various harsh natural environments.

Adopting a one-time pouring process, the outer membrane is an integral steel template, and the inner membrane is 15KG/m³ polystyrene foam for quick filling. Each section is equipped with structural compartments, and pre-embedded water and electricity pipelines and inspection slots. Adjacent floating bodies are cleverly connected by pre-buried connecting pieces to form a floating dock or pontoon bridge. The concrete structure floating body adopts a special cement formula and a unique pouring process, and the surface is smooth and smooth, and the amount of sleep is less than 0.5%/m³, which can effectively guarantee the safety and stability of the terminal.

3.Terminal accessories

Floating body: buoy and pontoon

Main structure: steel structure, aluminum alloy structure

Paving: plastic wood panel, solid wood panel

Anti-collision facilities: anti-collision strip, anti-collision ball

Mooring equipment: stainless steel mooring pile, aluminum mooring pile

Water and electricity installation: stainless steel water and electricity box

Fixing device: pile position fixation, anchoring device, strut fixation, I-steel guide rail

Movable approach bridge: steel structure approach bridge, aluminum structure approach bridge

Contact us